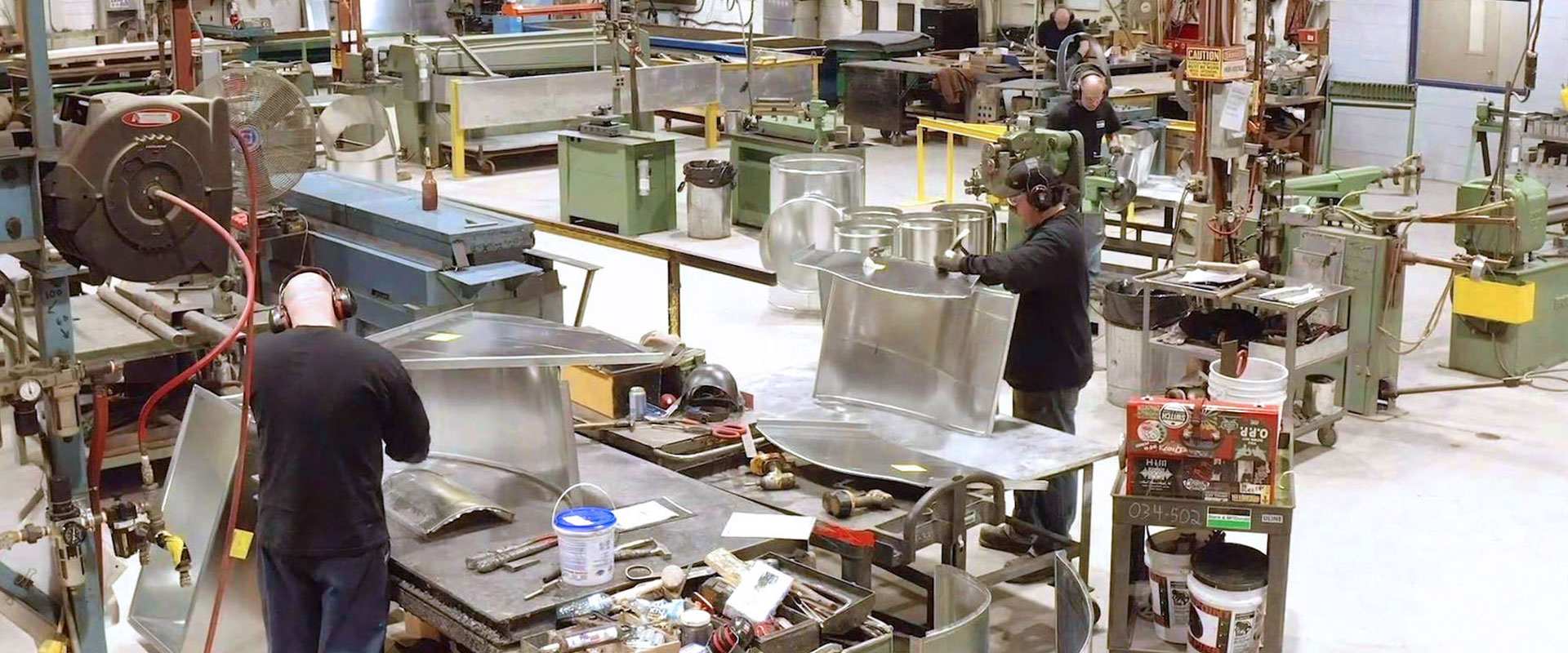

Fabrication &

Modular Construction

Versatile and precision offsite construction capabilities

All projects are not created equal, and in many cases customers need customized technical solutions to meet unique requirements. Black & McDonald’s ability to draw from our breadth of capabilities and experience ensures we can provide a customized solution that suits their needs.

With over nine decades of experience, Black & McDonald’s Sheet Metal and Custom Fabrication groups have provided sole-source and specialty metal solutions for every type of heating, ventilation, air conditioning, exhaust and environmental challenge. Our team works directly with design consultants to co-develop integrated models for both electrical and mechanical systems.

From piping to sheet metal, electrical, modular and custom fabrications, virtual construction and engineering services, B&M leads the way with:

- Building Information Modeling (BIM)

- Integrated Project Delivery

- Pre-Fabrication

- LEAN Construction

- Value Engineering

- Pre-construction Planning

The BIM/CAD modelling process plays a critical role in our approach to design, layout and installation. Our team uses these cutting-edge technologies to achieve optimal results in every aspect of a project’s construction. In particular, the results enable us to better plan and achieve full value engineering and cost savings in both labour and procurement.

Our BIM/CAD Virtual Construction team provides additional benefits in the form of modular construction. Using our technical expertise, we are able to identify those elements that can be prefabricated. For example, while work is being done on the site, a team can be concurrently building mechanical and electrical rooms, which are transported to the site when preparations are complete. These modules include structural steel, wiring, piping, HVAC, insulation and painting. It is a win-win solution that reduces site congestion while increasing productivity and schedule certainty.

Our fabrication capabilities reside in our Halifax, Ottawa, Toronto and Saskatoon facilities:

Railside Fabrication Facility

B&M has a 44,000 sq. ft. piping and miscellaneous metals heavy fabrication plant located at 77 Railside Road in Toronto, complete with onsite storage and an outdoor yard capable of fabricating pipes with a maximum diameter of 48″ and a maximum weight of 25 tons.

Pullman Court Sheet Metal and Custom Fabrication facility, Scarborough ON

- 26,000 sq. ft. facility with a production capacity of over 2 million pounds per year

- Fully automated coil line, two plasma cutting tables with Vulcan software, beam crane and hoists, and shear/brake/roll up to ¼” plate

- Design, fabrication and installation of all sheet metal to the most recent SMACNA standards

- Preassembly and modularizing sheet metal installation

- Coordinated delivery of metal to suit the pace of the installation, allowing for JIT or off-hour delivery

Ottawa Fabrication Facility, Ottawa ON

- 15,000 sq. ft. facility specializing in steel and stainless steel spool fabrication

- Novarc semi-automatic welding machine capable of welding 4” to limited 36” diameter pipes and capable of exceeding 200″+ a day

- 2 ton overhead crane.

- Plasma pipe cutting station supporting two production fitting stations

- Two welding stations equipped with positioners capable of handling up to 24” pipe diameter and 40 feet in length

- Two welding stations equipped with positioners capable of handling up to 12” pipe diameter and 20 feet in length

- Sunrise Hydraulic double cylinder Ironworker with shearing/ punching capabilities up to 1” plate

- Baxter Horizontal Band Saw with 18”x25” cutting capability

- ASME Boiler and Pressure Vessel Code Section VIII, Division 2; CSA Standard B51 Boiler, Pressure Vessel and Pressure Piping Code; CSA Standard W47.1 Division 3 Certified

Saskatchewan Fabrication Facility, Saskatoon SK

- 30,000 sq. ft. facility with over 22 acres of yard space and specializing in iron, aluminum, stainless steel, PVC and copper

- Vernon pipe cutting machine capable of processing pipe up to 48″ in diameter and 40 feet in length

- High-definition plasma arc cutting tables for plate profiling, allowing for cutting of 26 ga. 1-1/4″ plate to exact specifications

- Pipe spooling and fabrication procedures meeting rigid ASME specifications

- Four overhead cranes capable of lifting 3 tons each up to 14 feet above the shop floor

Explore Our Work

Get In Touch

Join Our Team

You believe that if something’s worth doing, it’s worth doing right. That solutions should be made to last. That being part of a team means working not just for oneself but for one another. That’s how we operate too.