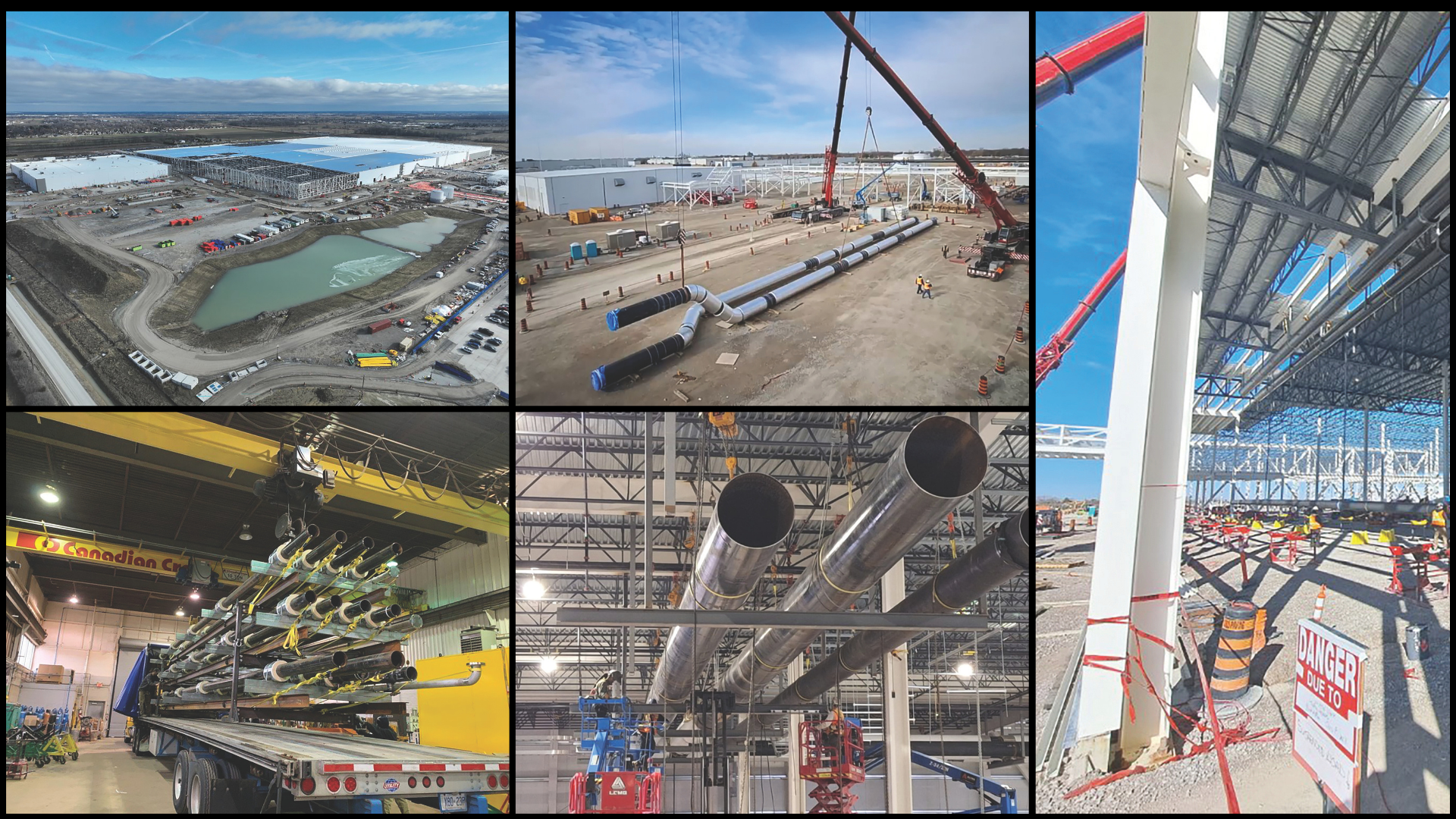

The new Stellantis plant in Windsor, Ontario, is not only the first facility of its kind in Canada, but also one of the largest projects in Black & McDonald’s history. Called NextStar Energy Inc., the $5 billion lithium-ion battery production plant is an innovative joint venture between Stellantis and LG Energy Solution, with support from the city, province, and federal government. B&M was awarded the contract for mechanical and HVAC in June 2022, and just a few weeks later, pre-construction was underway. Today, the massive facility is about 20% complete with an anticipated opening in April 2025.

Working directly under the design-build general contractor, Alberici-Barton Malow, Black & McDonald was brought on early during the design phase of the project as a trade partner rather than a typical subcontractor.

“This relationship allowed us to participate in the development of project execution strategies, schedule, and budget estimates at the 30, 60, and 90% design stages,” said Phil Jackson, Project Director. “It has helped us to improve project costs, schedule certainty, gain alignment around common project goals and agree on shared incentives, risks and rewards.”

In terms of scope, this unique and historic project is helping B&M strengthen its resource base and better position itself to pursue other large mechanical projects in the quickly expanding battery manufacturing industry in southern and southwestern Ontario.

“The on-shoring of battery manufacturing for EVs started as a trickle during the COVID-19 pandemic. Now it’s a tsunami,” Jackson said, pointing out that in 2019, just two battery factories were operating in the United States with another two under construction. Today there are about 30 battery factories either planned, underway or operational in the country. NextStar will be the first in Canada but there are many other automakers following close behind and providing exciting future opportunities for Black & McDonald.

“This is an exceptional time for our division and for me personally,” added Tim Peeters, Division Manager of Sheet Metal. “It’s a huge project, and a challenging one due to the ongoing design changes. The 3D model seems to evolve every day for this job!”

Featuring 5 million pounds of sheet metal, over 75 miles of hydronic and plumbing pipe, and 900 HVAC units, to name just a few of the impressive details, the main building occupies 3.5 million square-feet of the 4.5 million square-foot site—that’s roughly the size of 112 NHL hockey rinks. Currently, 550 B&M employees make up the staff, but that number is expected to rise to about 650 once the project hits peak momentum in the coming months.

“We’re talking about roughly 250,000 feet of duct work, 80,000 feet of fabric duct, and 120,000 feet of flue venting,” said Stephen Payton, Sheet Metal Project Manager. “It’s a massive amount of work in a short timeframe amid constant design changes. The vast manpower needed to complete this project is intense.”

Not only is this a first-of-its-kind project for most of the B&M staff, but according to Payton, it’s also the single, largest sheet metal contract ever in Ontario. Stellantis and LG Energy’s goal for the Windsor plant is to make it the leading EV-battery hub on the continent, and the first of many plants of its kind coming soon to the province.

Technology & Innovation

Given its mission to revolutionize the North American EV industry, it’s no surprise some unique applications and new technologies were used to steer the mega-project toward what will no doubt be a successful finish. According to John Stickney, Design Lead & Project Superintendent, design assist and value engineering were used from the early stages and have been integral to keeping the project on track.

“As industry leaders in 3D modelling and visual design, our experience allowed us to help the client in leading clash coordination to assist the project for all trade partners. This has been a real asset,” he said. “Modelling and creating clear installation drawings helped us provide shared hanger loading data and 100% spooled piping systems, which enabled us to deliver on the tight schedule at the prefabrication stage, as well as the field execution stage.”

Navis, Revit, BIM 360, Procore, Blue Beam, and P6 are just some of the software systems Stickney and his team have been using. Putting a heavy focus on utilizing prefabrication to reduce man hours on site and save on field installation time, prefabrication in the shop has helped speed up assembly time to achieve a difficult schedule.

“Given the enormity of the plant and the sheer number of components within it, a massive, heavy-lift helicopter operation will be used to transport the 500 pieces of equipment to where it needs to go, from 25,000 lb. per down, in addition to the construction cranes,” he said. “We have 18,500 tons of cooling—almost 28,000 GPM—which is enough cooling for 7,500 homes. It is hard for most people to fathom the size and scope of this project, even for those of us working on it.”

Currently, the contract represents $500 million for B&M, but that number is expected to hit $650 million by the time the facility opens next year.

B&M would like to acknowledge all those currently contributing to the success of this world-renowned project, including:

Bruno Gatti, General Manager, Mechanical Construction

Tim Peeters, Division Manager, Sheet Metal

Robert Campbell and John Brosens, Shop Managers

Phil Jackson, Project Director

Chad Fenech, Construction Manager

Jonathan Stickney, Mechanical Design Lead

Project Managers: Stephen Payton, Kevin Robitaille, Sourabh Sangwan, Conor Malone, and Jacob Paul

Site Superintendents: Oliver McMeo, Guy Krisza, Ian Roberts, Jeff Sinclair and Keith Wright